Detection units for electron microscopy

Key properties

We produce and deliver a range of detection and imaging units based on our own unique scintillation materials

- Very good luminescence efficiency

- Unlimited operating lifetime

- OEM production, testing and certification

Production range of microscopy detection units covers detectors for scanning (SEM) and transmission (TEM) electron microscopy.

| SEM detectors | ||

|---|---|---|

| SE (secondary electron) detection |

|

|

| BSE (back-scattered electrons) detection |

|

|

| CL (cathodoluminescence) |

|

|

| TEM detectors | ||

| STEM detectors |

|

|

| TEM detectors |

|

|

Crytur cooperates closely with customers on the design and development and can also deliver special detector designs according to the custommers needs.

Crytur also provides a solution for SEM upgrades. See REBEKA™ to learn more about the motorised vacuum detection system with read-out electronics.

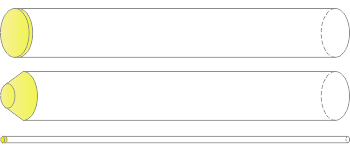

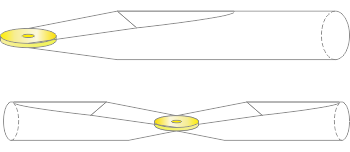

Lightguides

Crytur produces many types of light guides for different detectors and detection units. A variety of raw materials are used depending on the scintillation material and application:

- PMMA with enhanced UV transmission

- quartz glass

- sapphire

Other materials can be used on request.

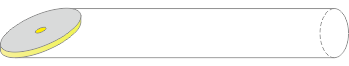

Functional coating

The detection scintillator surface is coated to prevent charging, to increase the light output and to protect the scintillator surface.

Conductive coating

- Al (for light-tight coating, detection surface)

- ITO (detection surface, high chemical and mechanical resistance)

- CRYTUR low-energy coating (detection starting from 500V)

High reflectivity / Anti-reflection / Protection

- Al (high reflectivity)

- ITO (internal total reflection, mechanical resistance)

- Au (stop layer)

- MgF2 (anti-reflection)