KARMEN™ - retractable BSE detector for hot stage

Key properties

| RELIABLE SENSOR | PRECISE MECHANICS |

|---|---|

|

|

Examples of measurements acquired with KARMEN™

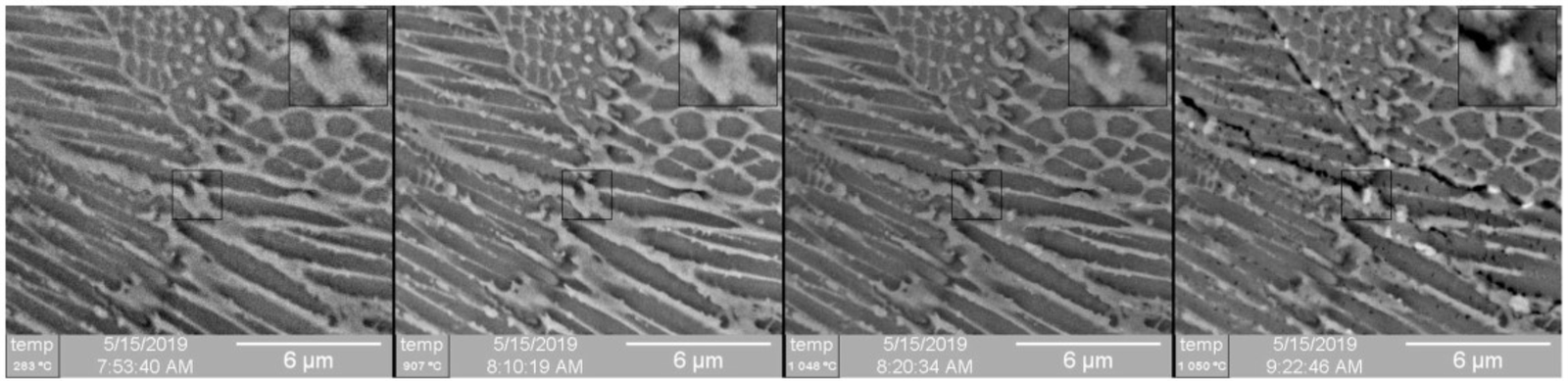

Series of images recorded at high temperature in high-vacuum conditions during the recrystallisation of multiphasic high-temperature alloy using the Karmen BSE detector. The inlet corresponds to a magnification of the 2 ×2 µm2 central zone.

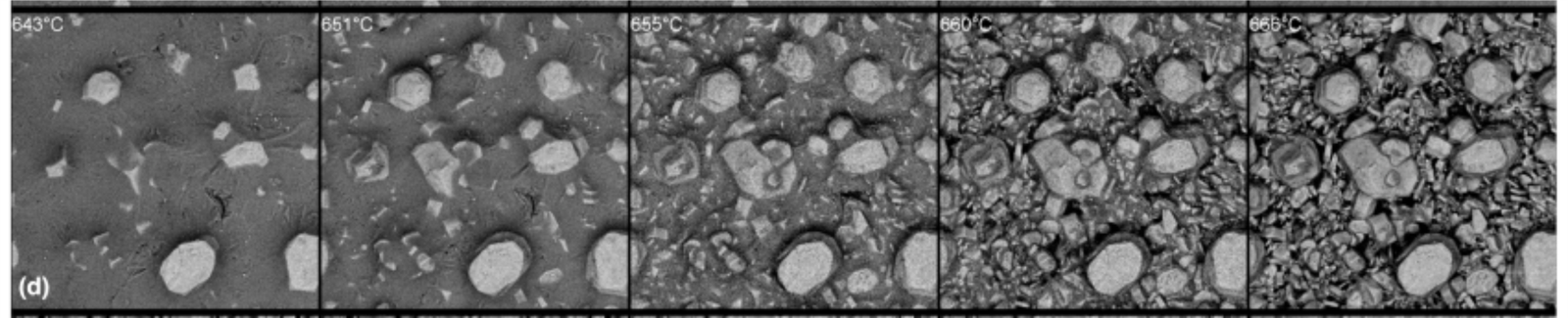

Heat treatment of an Al-Si coated steel from room temperature to 900°C with a 20°C/min heating ramp. Selected BSE images representative of the different observed fast phase formation due to the melting of the coating between 643°C and 666°C.

Images with courtesy Podor R, Mendonça J, Lautru J, et al. Evaluation and application of a new scintillator-based heat-resistant back-scattered electron detector during heat treatment in the scanning electron microscope. Journal of Microscopy. 2020;1-15.

Heat management

SENSOR HEAT MANAGEMENT

|

|

SENSOR SHIELDING

|

|

Technical parameters

-

SENSOR UNIT

|

single crystal scintillator with optimized efficiency and minimized afterglow, exponential decay time 45 ns with 30 photons/keV Outer diameter 15 mm Inner hole diameter 3 / 2 / 1.5 or 1 mm. This dimension limits the field of view Sensitivity down to 10pA beam current Allows a 7 mm working distance |

|

-

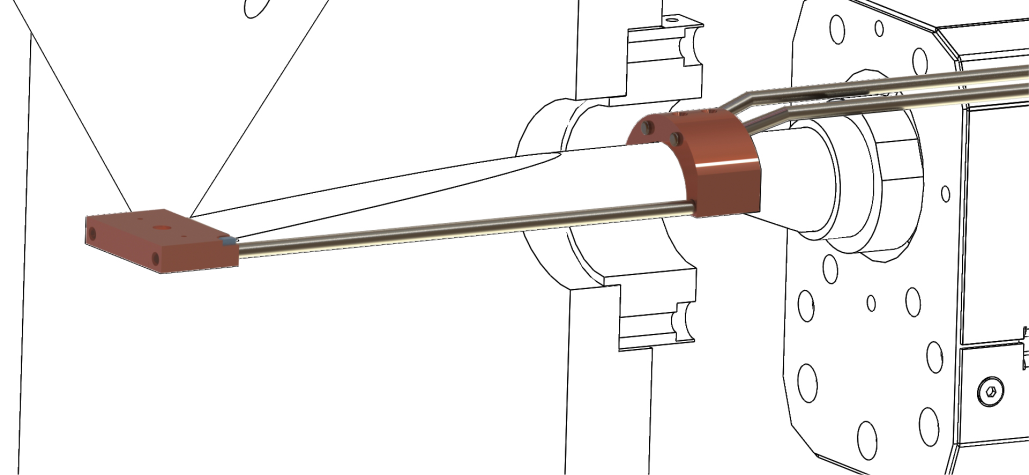

MECHANICAL UNIT

|

Dimensions 406 x 100 x 72 mm Bellows design for ultimate vacuum 140 mm motorized retraction +/- 2 mm fine adjustment in x, y, z axis 0.01 mm repeatability Flange adapted to customer's SEM Silver / black / blue / red matt surface finish available |

-

ELECTRONICS CONTROL UNIT

|

Dimensions 270 x 180 x 65 mm Supply 230/110 V 3 noise filters optimized for different scanning speeds 50 MHz bandwidth Internal source 0-1200 V for PMT HV Output video signal -1/+1V (-5/+5V) Full remote software control DC offset up to -20V |

|